Foam and bundled lines are now a relic of the past

It’s often the smallest details that cause the biggest problems. In new construction, the roof may account for just 2% of the total building cost — yet it represents 75–80% of post-construction litigation. Much of that litigation stems from water intrusion at the very spots contractors must cut to run refrigerant and electrical lines: roof and wall penetrations. These seemingly minor openings are a major vulnerability.

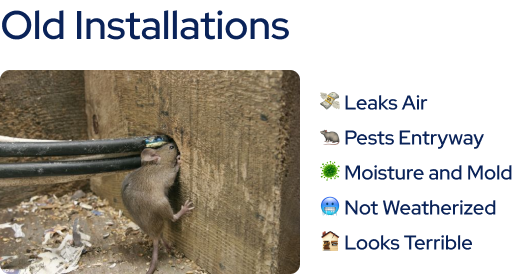

For decades, contractors and engineers have accepted a patchwork approach when it comes to threading HVAC components through this critical barrier—cutting a hole, bundling lines, and then slopping on foam or globs of caulk.

The most common method is foam, which is gaining a reputation for being highly prone to degradation, leaks, and a convenient point of access for a variety of critters.

Luckily for the building owners, foam is also increasingly no longer code-complaint in most areas.

Companies are looking for innovative and new solutions to replace foam, and products like the Titan Outlet and E-Flex Guard, from Airex Manufacturing, are becoming the new industry standard. While it may be more expensive than a standard can [CP1] of foam – it offers a fully engineered, tested-and-proven, code-compliant solution that eliminates all of the guesswork and reduces liability while protecting the building from leaks and the contractor’s reputation from tarnish.

The Failure of Foam

To stay competitive with their bids, HVAC contractors will occasionally use cost-cutting measures, but the roof isn’t the place to do that.

Foam is a great shortcut in this vein—it’s cheap, fast, and even inexperienced technicians can be tasked with filling gaps between critical lines and the roof.

However, when you look at most foam installations, it becomes clear that the material can be vulnerable to UV exposure over time. Additionally, if any repairs or upgrades are needed, maintaining or modifying the foam can present significant challenges.

Multiple refrigerant lines being jammed through a single roof penetration, and then hit with foam, is a recipe for disaster. Not only does it degrade, but expanding foam does only that—it expands, but does not contract. It also does not doesn’t accommodate the expansion/contraction cycles associated with refrigerant lines, which is also required by newer codes.

Foam also does not do well with vibration, another staple of a refrigerant line. These vibrations and added frictions can break down foam and turn it into powder, a guaranteed avenue for leaks.

Gooseneck penetrations, perhaps a step up from foam, are good for a few projects or lines, but scale problems emerge in multi-unit/multifamily where dozens of lines cross the roof — each additional penetration raises leak risk and labor.

All of these failure points can not only lead to a very dissatisfied customer, but may also result in delayed inspections and failed water load tests.

Enter the Airex Pro-System Kit

While choosing higher-quality materials may involve a greater upfront investment, the long-term benefits—such as improved system performance, reduced call-backs, and greater peace of mind—often justify the cost and deliver solid return on investment over time.

The “doghouse,” or penetration box, creates a vertical entry that’s not only easier to work with, but also dramatically reduces the chance for leaks.

Within the system, multiple systems (pipe, electrical) can be brought through a single, sealed structure, where there’s only one bend instead of multiple, which is superior for pipe integrity.

- Titan Outlet™: A wall-mounted outlet seal that provides a compression gasket around HVAC piping at the point of exterior wall or parapet penetration.

- E-Flex Guard™: A UV- and weather-resistant PVC cover that protects exterior refrigerant pipe insulation and maintains vapor barrier integrity.

Together, they create a sealed, supported, and serviceable solution that meets or exceeds all major code requirements — and withstands the real-world rigors of rooftop installation.

Engineered for Peace of Mind, Built Strong Enough for the Field

The Titan + E-Flex system isn’t a retrofit of unrelated parts — it’s a purpose-built product line designed from the ground up for HVAC contractors, engineers, and building owners.

Titan Outlet™ Features:

- Made from durable ASA polymer with an over-molded Santoprene elastomeric sleeve

- Gasketed seal conforms to irregular surfaces and allows for movement and vibration

- Fastened using ICC-ES listed, Miami-Dade approved hardware

- Forms a mechanical connection (not adhesive-based) with E-Flex Guard via stainless steel clamp

- UL-rated for outdoor exposure (UL 746C, F1), flame tested (UL 94 HB), and meets ASTM standards for air and water sealing

E-Flex Guard™ Features:

- Made from UV-resistant PVC, protecting pipe insulation from solar and physical damage

- Dual-bonded hook-and-loop fasteners are welded and stitched for longevity

- Class II vapor retarder (ASTM E96), fire-rated (ASTM E84 / UL 723), antimicrobial, and reusable

- Available in sizes up to 1.5″ insulation thickness for new heat pump standards

Aside from lowered liability for the contractor and fewer callbacks, this system provides improved insulation, which translates to less strain on expensive equipment.

Improved insulation integrity also better maintains thermal conductivity, which helps to preserve equipment over time.

With poor insulation, more heat is picked up on the return line. This causes the unit to work harder, reducing the life of the system. Leakage around the penetration means conditioned air leaves space, making the unit kick on more often to make up.

Howard Ahern, National Sales and Technical Manager at AIREX Manufacturing, said he’s heard from contractors who installed the Titan system over 10 years ago that look like they were put in last week. The UV-resistant material has proven itself in the field long before it was used in the roof protrusion application—in fact, it’s been used as the encasing material for roadside emergency phone boxes for decades. If one of the Titan outlets can survive on a roof in Palm Springs, where temps can hit 124°F in the sun, and not show any fading or cracking after 25 years, contractors can sleep easy at night knowing the product they installed is going to last.

In fact, Airex believes in their product enough that it comes with a 10-year warranty.

The Retrofit Advantage

This might be where the Titan system shines the brightest—as an upgrade offered to a building owner following the decarbonization trend, where older rooftop penetrations need to be replaced and the system requires more than one line.

The two-piece system works great with existing rooftops, and can accommodate oversized insulation (1″ and 1.5″) often required for heat pumps in commercial applications, like VRF systems and commercial heat pumps

The other added benefit is that this future-proofing against code changes down the road due to the simplicity of swapping out old infrastructure.

Code Landscape: The Days of ‘Old Tricks’ Are Numbered

Codes, regulations, and standards are rapidly evolving.

Simply put, when it comes to roof penetrations, it’s not 2012 anymore—bundled lines, hole saws, and foam are no longer going to fly with inspectors.

Across the country, the 2021 International Energy Conservation Code (IECC) — and in many jurisdictions, the newer 2024 version — is now the standard. These codes represent a significant tightening of building envelope requirements.

Here’s what’s changed:

- C402.5.1.1: All penetrations must be sealed to prevent air leakage, and that seal must accommodate mechanical vibration and material expansion/contraction.

- C403.12.1: Outdoor pipe insulation must be protected against UV, moisture, and physical damage, and be removable for service.

- C402.4.2: Penetrations must be sealed without compromising the continuous air barrier.

- IMC 1109.4 / UMC 1107.6 (2021/2024): Refrigerant pipe penetrations must be sealed in an approved manner — not spray foam.

The Titan + E-Flex system was designed specifically to meet these requirements, using gasketed mechanical seals and non-adhesive fasteners to create a durable, serviceable barrier.

A contractor’s playbook should also be updated:

● All line sets, electrical, and controls routed through a protected chase.

● Sealed terminations at vertical surface using molded polymer outlet assemblies (sizes to accommodate bundle counts).

● Factory components tested for air & water leakage; gasketed, bolted access.

● Fewer roof penetrations, cleaner layout, faster repeatable install sequence.

There have been reports of projects where spray foam has already degraded before the building even opened. Foam is a cheap method, which is inevitably going to lead to problems. Ultimately, a contractor is going to be paying for it twice—making it not worth the gamble.

The Details Defend the Systems

The goal for an HVAC contractor is to create systems that not only give customers what they’re paying for, but also showcase their integrity and increase their reputation. In this case, rooftop penetrations may be a small part of a big picture, but here they carry an outsized risk.

The Titan Outlet + E-Flex Guard system eliminates that risk. It replaces guesswork with engineered certainty. And in an era of tighter codes, high-performance buildings, and razor-thin margins, it offers something every contractor and engineer needs: peace of mind.